BRUSHING AND DEBURRING MACHINES

The Pola e Massa product range for metal and alternative materials includes heterogeneous equipment for finishing applications. In particular they are mainly focused on processes like:

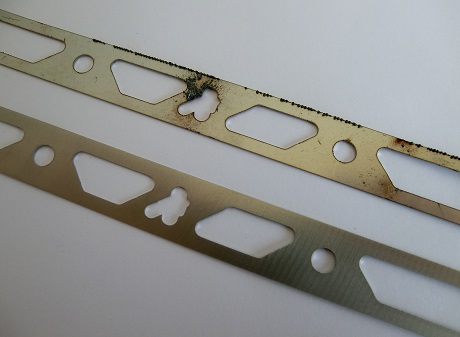

- Oxide removal

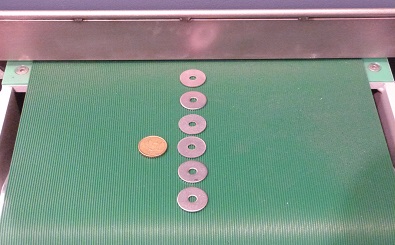

- Holes, edges, corners and slots deburring

- Aesthetic brushing

- Satin finishing

- Slags removal

- Getting expected surface roughness

- etc...

All Pola e Massa machines are designed to meet various requests coming from customers, even the most demanding, paying special attention to processes, organization and costs/benefits ratios.

The brushing/deburring machines designed and produced by Pola e Massa, normally provided in 2 or 4 brushes modules, are suitable to get single side or double side treatment, and their functionalities can be also implemented adding a wide range of complementary accessories:

- Filtering systems (i.e. using cartridges, fabric rolls, etc…)

- Washing systems, with standard and high pressure configurations (i.e. 10 bar - 145 PSI, 30 bar - 435 PSI, 100 bar - 1450 PSI, High flow, Ultrasonics, etc…)

- Air Cleaning systems (i.e. blow off)

- Conveying systems (i.e. transport systems using rollers and/or belt, etc…)

- Automatisms (i.e. centering tools, thickness readers, board alternators, data matrix collector, etc…)

- Degreasing equipment

- Automation systems (i.e. loaders, unloaders, buffering systems, orthogonal diverters, etc…)

The Pola e Massa product range gives customers the opportunity to mainly select two main basic configurations:

UNIBLOC

It refers to compact size machines, very often including in the same frame brushing, washing and eventually drying process.

MODULAR

It includes a wide range of possible high performing configurations, both in term of used technology and process complexity. This choice allows to get your own customized and flexible configuration, able to guarantee expected results even in the more complex processes.

Both configurations, Unibloc and Modular, can be ordered considering three different levels of automatisms:

A) MANUAL, where operators are forced to manually set main operative parameters (i.e. brushing positioning, water pressures, air pressures, etc…) of the mentioned equipment during the whole manufacturing process.

B) SEMI-AUTOMATIC, which allows operators to only set some operative parameters (i.e. thickness of incoming pieces) of the machine, while others (i.e. brushing positioning) are automatically managed by the machine PLC.

C) FULL-AUTOMATIC, where operators activities are reduced to a very few initiatives during the whole manufacturing processes.

On request are available several accessories and customized solutions.

Pola e Massa also provides a complete range of brushes, both in term of materials used and requested finishing.

Here below you can find some brushing machines examples currently included in the Pola e Massa product range:

Mod. Unibloc 4/25/FA – 120. Brushing machine with conveying system using rollers and n. 4 horizontal brushes. Washing, rinsing and drying included. Wet process and suitable for double side treatment.

Mod. Unibloc T/12 VM. Brushing machine with conveying belt and n. 2 vertical brushes. Dry process and single side treatment. Suitable for small size pieces.

Mod. T/25/FA. Brushing machine with conveying belt and n. 2 horizontal brushes. Washing, rinsing and eventually drying on request. Wet process and singles side treatment only.

In order to find your own configuration, able to perfectly meet your needs and technical requirements, do not hesitate to contact Pola e Massa engineers.

e-mail: sales@polaemassa.com

Tel. +39 0143 83.77.11

Fax +39 0143 800.12